The On-board charger (OBC), also known as the vehicle-mounted charger, is, as the name suggests, a charger fixed to electric vehicles. It has the ability to charge the vehicle's power battery safely and automatically. OBC is primarily used in electric vehicles that require "plug-in" charging, such as pure electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs).

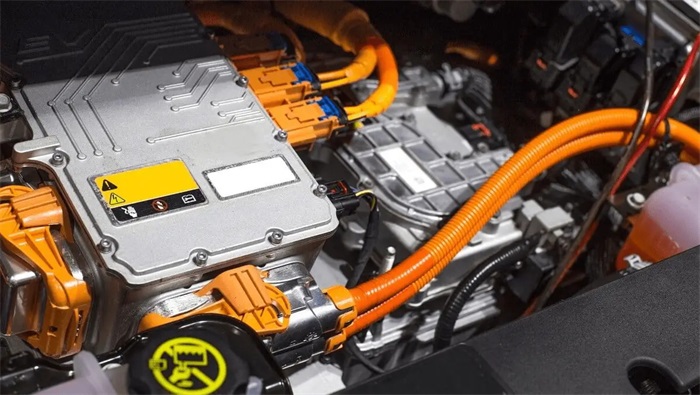

As the interface between electric vehicles and the public grid, the OBC converts alternating current (AC) from the grid into direct current (DC) required by the vehicle's high-voltage battery to charge it. It can also convert the DC from the vehicle's power battery into AC and feed it back to the grid, achieving energy conversion between the vehicle's battery and the grid.

The OBC provides essential protections during charging, including overvoltage, undervoltage, overcurrent, and undercurrent safeguards. If an issue arises, it immediately disconnects the power supply. To enhance safety, an electrical isolation layer with a 2500V-3750V voltage withstand capacity is usually required between the grid and vehicle side, known as an isolated OBC. Most electric vehicles today use isolated on-board chargers.

In general, on-board chargers can be classified into unidirectional, bidirectional, and integrated on-board chargers.

Unidirectional On-Board Charger (Uni-Directional On-Board Charger): Power flows in one direction, typically using high-frequency switch-mode power supply technology. The topological structure can be single-stage or two-stage. It only has charging functionality.

Bidirectional On-Board Charger (Bi-Directional On-Board Charger): Power flows in both directions, often using a two-stage conversion structure, consisting of a bidirectional AC-DC converter and a bidirectional DC-DC converter. It not only has charging functionality but also an inversion function.

1. Charging Function: Power is drawn from the grid through an AC charging station and AC charging port, which connects to the OBC to charge the vehicle's power battery.

2. Inversion Function:

● V2L (Vehicle to Load) Inversion Function: Power is drawn from the vehicle's power battery, passed through the bidirectional OBC, and the AC charging port to supply 220VAC power to external electrical devices.

● V2G (Vehicle to Grid) Inversion Function: Power is drawn from the vehicle's power battery, passed through the bidirectional OBC, and the AC charging port, then connected to the grid.

Integrated On-Board Charger:

1. Integration of OBC, DC-DC, and PDU in vehicle power systems: OBC+DC-DC integrated, OBC+DC-DC+PDU integrated.

2. Integration of motor, controller, reducer, OBC, DC-DC, BMS, and other components into the vehicle powertrain and on-board power system: multi-in-one integration.

The OBC circuit mainly consists of the power circuit and the control circuit. The power circuit is divided into two stages:

1. Power Factor Correction (PFC) Stage: This stage converts AC voltage from the grid into DC voltage and ensures that the input AC current is in phase with the input AC voltage. Depending on the power requirements, multiple parallel boost circuits may be used to expand capacity.

2. DC-DC Converter: This stage receives DC output from the PFC stage and converts it into the voltage required for battery charging. The output voltage and current of the converter change over time based on the overall health and charging state of the battery. Depending on the power requirements, multiple parallel DC-DC circuits may be used for expansion. Common DC-DC circuit topologies include phase-shift full bridge and LLC.

Currently, the design goals for OBCs are oriented towards high-frequency operation, high power factor, and high efficiency. Different topologies are adopted depending on the power level. Typically, as power increases, overall system losses also increase. However, SiC-based power devices have advantages such as low capacitance, low conduction resistance, and high temperature and voltage resistance. These advantages reduce the number of components, improve efficiency, and reduce the size, weight, cost, and complexity of the OBC.

Next:CALB 1.2MWh Marine Battery System Powers Saudi Aramco's Hybrid Vessel Trial Voyage

Previous:EVE Energy Unveils 836kWh Split Module Cabinet at SNEC 2025

Contact Person: Miss. Kiki

| WhatsApp : | +8617763224709 |

|---|---|

| Skype : | +8617763224709 |

| WeChat : | +8617763224709 |

| Email : | kiki@lifepo4-battery.com |