Forklifts are indispensable in various industries, and their performance heavily relies on the type of battery used and how it is maintained. Whether you use lead-acid or lithium-ion batteries, understanding the correct charging procedures, key differences between technologies, and their respective benefits is essential for optimizing efficiency, safety, and cost-effectiveness. This article provides a detailed overview of these aspects to help you make informed decisions for your operational needs.

Proper charging is critical to extending the life and ensuring the safety of lead-acid forklift batteries. Follow these steps for optimal performance:

1. Preparation

● Consult the battery and charger manuals: Always adhere to manufacturer-specific guidelines.

● Ensure proper ventilation: Hydrogen gas emitted during charging requires a well-ventilated area.

● Clear the charging area: Remove flammable materials and ensure easy access to the battery.

● Wear personal protective equipment (PPE): Safety glasses and gloves are strongly recommended.

2. Charging Process

● Connect the charger correctly: Match positive-to-positive and negative-to-negative terminals.

● Set appropriate parameters: Adjust voltage and current according to battery capacity and charger specifications.

● Monitor the process: Regularly check temperature, electrolyte levels, and indicator lights.

● Disconnect when fully charged: Avoid overcharging to prevent damage and reduced lifespan.

3. Additional Tips

● Use an automatic timer to prevent overcharging.

● Limit topping-up charges to avoid degradation.

● Perform periodic equalization to balance cell voltages.

● Maintain electrolyte levels with distilled water.

● Keep terminals clean and store batteries in a cool, dry place.

Safety should always be the top priority. When in doubt, consult a qualified technician.

Lithium-ion batteries offer distinct advantages but require specific charging practices:

Preparation

● Review manufacturer manuals: Understand unique requirements for your battery and charger.

● Ensure ventilation: Although lithium batteries don’t emit harmful gases, proper airflow is still important.

● Clear the area: Remove flammable materials and ensure accessibility.

● Wear PPE: Safety glasses and gloves are recommended.

Charging Process

● Connect the charger: Verify terminal polarity.

● Rely on automatic settings: Most lithium chargers manage charging profiles independently.

● Monitor temperature and indicators: Perform occasional checks during charging.

● Disconnect when fully charged: Even with auto-shutoff, confirm completion manually.

Additional Tips

● Utilize opportunity charging: Short, frequent charges during breaks enhance flexibility.

● Avoid high-temperature environments to preserve battery health.

● Store batteries in a cool, dry place at around 50% charge for long-term periods.

● Follow manufacturer guidelines for extended storage.

Though low-maintenance, adhering to best practices ensures longevity and performance.

The chargers for these battery types are not interchangeable due to fundamental differences in technology and requirements:

1. Charging Technology

● Lithium-Ion: Employs multi-stage charging with precise voltage and current control for safety and efficiency.

● Lead-Acid: Uses simpler mechanisms with fewer safety and monitoring features.

2. Charging Speed

● Lithium-Ion: Charges significantly faster, often within hours.

● Lead-Acid: Requires longer charging times, typically overnight.

3. Features and Functionality

● Lithium-Ion: Includes advanced capabilities like temperature monitoring, data logging, and communication protocols.

● Lead-Acid: Lacks sophisticated features and is more basic in operation.

4. Cost

● Lithium-Ion: Higher initial cost but offers long-term savings.

● Lead-Acid: More affordable upfront but may incur higher maintenance and replacement expenses.

Each charger type is specifically designed for its corresponding battery chemistry. Cross-compatibility is not recommended.

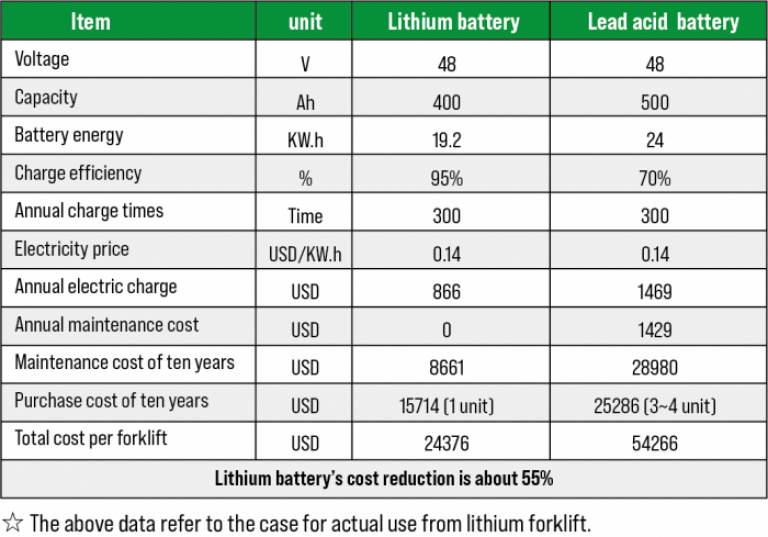

Total Cost of Ownership Comparison Charts

5. Overall

Lithium-ion chargers provide faster charging, smarter features, and greater efficiency, while lead-acid chargers are more budget-friendly. Your choice should align with operational needs and financial considerations.

Performance Powerhouse

● Faster charging reduces downtime and enhances productivity.

● Longer lifespan (2–3 times that of lead-acid) lowers replacement costs.

● Sustained power delivery without voltage sag ensures consistent performance.

● Higher energy density improves efficiency and reduces energy consumption.

Operational Efficiency

● Opportunity charging allows for quick top-ups during short breaks.

● Minimal maintenance eliminates watering and acid checks.

● Compact and lightweight design enables better maneuverability.

Environmental Impact

● Eco-friendly with no toxic materials or acid spills.

● Reduced CO₂ emissions support sustainability goals.

● Aligns with modern environmental regulations and practices.

Additional Advantages

● Enhanced safety with no flammable gas emissions.

● Quieter operation improves workplace conditions.

● Higher resale value due to advanced technology and durability.

Investment Considerations

Although lithium-ion forklifts involve a higher initial investment, their long-term benefits—such as the 55% cost reduction demonstrated by Hangcha Group’s lithium-ion line—often justify the upfront expense.

Selecting the right battery technology and adhering to proper charging and maintenance protocols are crucial for maximizing the efficiency, safety, and service life of forklift batteries. While lead-acid batteries remain a cost-effective option for some, lithium-ion batteries offer superior performance, reduced operational costs, and environmental benefits. By understanding these differences and following best practices, businesses can enhance productivity and contribute to a more sustainable future.

Next:HiTHIUM 1175Ah Battery Powers Landmark 4GWh Saudi Energy Storage Project

Previous:Sungrow Launches Next-Gen Microinverter S2500S-L for Brazilian Market

Contact Person: Miss. Kiki

| WhatsApp : | +8617763224709 |

|---|---|

| Skype : | +8617763224709 |

| WeChat : | +8617763224709 |

| Email : | kiki@lifepo4-battery.com |